E-Clad is an E-volutionary New Alternative to Hard Chrome Plating

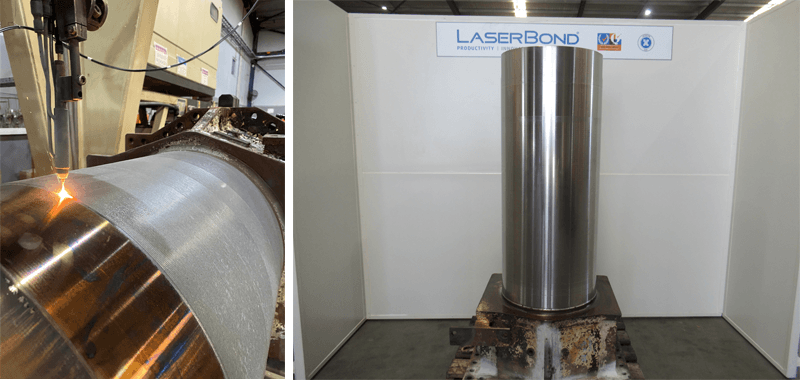

LaserBond® E-Clad is a break-through surface engineering product developed by Gregory Hooper, providing a laser cladding overlay that replaces hard chrome on cylindrical surfaces. It actively protects both people and the environment by not using any carcinogenic Hexavalent Chromium processes. This cladding method also uses less than 25% of the energy used when hard chroming – adding to the E-Clad’s already excellent environmental profile.

The benefits don’t stop there – E-Clad treated components are more impact resistant, have significantly better abrasion and corrosion resistance than the chemical bond produced by hard chroming. In fact, in independent testing, E-Clad provided a wear rate 3 - 10 times lower than commercial chrome coatings and corrosion rates 2-3 times better. E-Clad’s superior cladding means extended wear life because equipment operates for longer and there’s fewer planned and unplanned shutdowns. The E-Clad application process is also reduced, providing faster turn-around times, mitigating the delays inherent in electroplating.

E-Clad replaces the negative effects of chroming on both people and the environment, enhances efficiencies, reduces downtime, increases wear life, and in doing so, improves our customers bottom line.

Download our product application document here >> PDF