Utils

Videos

Heat Treatment Vacuum FurnacesThis video showcases our Heat Treatment capabilities. We have 3 x Abar- Ipsen positive pressure quenching vacuum furnaces and 2 air recirculating tempering furnaces, providing state of the art heat treatment for air hardening materials to 1300 degrees Celsius. Cooling pressure up to 6 Bar. Capacity to 600 x 600 x 900 m. |

GrinderWe have a range of equipment for grinding including, Cylindrical grinders to Ø1250mm swing x 5000mm between centres. This video showcases one of our largest grinders at our Smeaton Grange, NSW workshop. |

Grit BlasterOur grit blaster machinery and booth is a newly installed, state of the art set up, located at our Smeaton Grange, NSW workshop. This video showcases the grit blaster in operation. |

Horizontal BorerWe have Horizontal machining centres including CNC horizontal boring and facing to 4000 x 2300 x 2300mm. This video showcases our large horizontal borer which is located at Smeaton Grange, NSW. |

HVOF Thermal SprayThis video showcases our HVOF thermal spray in action. In total across all our facilities, we have 7 x booths equipped with robotics and component manipulation up to 1600 dia. x 4000mm length. Additionally, we have an HP HVOF (x4), HVAF (x2), Arc spray (x8), Air Plasma spray, combustion wire and combustion powder spray systems. |

LaboratoryOur R&D team is fully equipped with an in-house laboratory to conduct testing and examination. One of the main tools for this research is our Scanning Electron Microscope (SEM), which is showcased in this video. The SEM allows for investigation of surface engineered layers and base material metallurgy down to the nanoscale. |

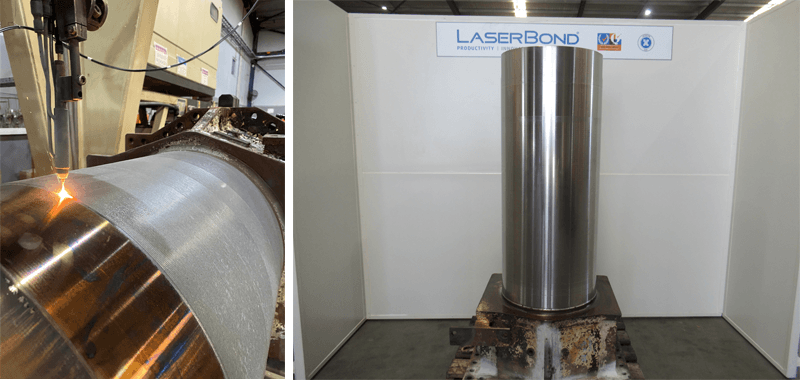

LaserBond Cladding (Laser 7 - Smeaton Grange, NSW)This video shows our newly commissioned laser in testing and set up phase. It is an automated 8 kW multi robot LaserBond® cladding cell, incorporating robotic pick and load system with measurement capability and integrated thermal control. |

LatheThis video showcases our largest lathe at our Smeaton Grange, NSW workshop. We have CNC lathes to Ø400mm x 2200mm between centres. Conventional centre lathes to Ø1600mm x 8000mm between centres CNC Vertical lathe boring to Ø3000mm x 2500mm. In our QLD facility we have a manual lathe with a swing of 2000mm x 5000mm long. |

MetrologyIn this video we showcase well-equipped metrology lab capable of stabilising large objects of up to 3.5T ready for dimensional checks and reporting with our portable CMM and a variety of other equipment, as well as the ability to measure hardness and surface finish. |

MillThis video showcases one of our CNC milling machines in operation, this mill operates to 3000mm x 900mm x 900mm and is located at Smeaton Grange, NSW facility. |

Vertical BorerIn this video our CNC Vertical lathe boring machine is filmed in action at Smeaton Grange, NSW. It operates to Ø3000mm x 2500mm and can accommodate a wide range of jobs. |

Large Cylindrical Grinding & Super FinishingGrinding and super finishing are both core functions of surface engineering and both are available at LaserBond Victoria. With the ability to super finish to mirror finish on cylindrically groundcomponents Ø500mm x 5000mm between centres. This video showcases these capabilities at our Altona, Victoria workshop. |

Plasma/ APS Thermal SprayAtmospheric Plasma Spray (APS) is the most versatile and flexible thermal spray. We have the capability to apply APS coatings at our Altona, Victoria workshop. This video showcases the APS thermal spray in action. LaserBond is a licensee of a range of traction and release coatings developed by Plasma Coating International. Coatings combine a thermal spray bond coat with a polymer topcoat. |

LaserBond Cladding (Laser 8 - Altona,Victoria)We have recently installed and commissioned our eighth advanced Laser Cladding cell (Q3 2021. This cell is the first Laser Cladding cell to be introduced into our Victorian workshop in Altona. The specifications are impressive, comprising of 8kW diode LaserBond® cladding cell with integrated 6 axis robotic work processing, coupled with a 2 axis centre capable of cladding complex geometries and internal bores), and providing up to 10T capacity and handling up to 2m diameter and 6m in length. |

PTA HardfacingThis video shows our PlasmaTransferred Arc (PTA) coating equipment in action at our Melbourne facility. This video showcases this versatile automated process for depositing a range of alloys and high hardness, metallurgically fused composite materials onto a range of substrates. |

Spray and FuseSpray and fuse is a thermal spray process that creates a metallurgical bond between the coating and the surface. This video showcases our spray and fuse capabilities at our Altona facility. |

LaserBond Cladding (Laser 3 - Smeaton Grange, NSW)This video shows our LaserBond® cladding cell in operation at our Smeaton Grange workshop. Our Laser 3 is an 8kW diode LaserBond® cladding cell with integrated 6 axis robotic work processing, coupled with a 2 axis manipulator centre capable of cladding complex geometries and internal bores. Showcasing our range of capabilities to laser clad many components in various shapes and sizes. |

Vic Customer Event - Feb 2022

E-Clad Laser Cladding

E-Clad is an E-volutionary New Alternative to Hard Chrome Plating

LaserBond® E-Clad is a break-through surface engineering product developed by Gregory Hooper, providing a laser cladding overlay that replaces hard chrome on cylindrical surfaces. It actively protects both people and the environment by not using any carcinogenic Hexavalent Chromium processes. This cladding method also uses less than 25% of the energy used when hard chroming – adding to the E-Clad’s already excellent environmental profile.

The benefits don’t stop there – E-Clad treated components are more impact resistant, have significantly better abrasion and corrosion resistance than the chemical bond produced by hard chroming. In fact, in independent testing, E-Clad provided a wear rate 3 - 10 times lower than commercial chrome coatings and corrosion rates 2-3 times better. E-Clad’s superior cladding means extended wear life because equipment operates for longer and there’s fewer planned and unplanned shutdowns. The E-Clad application process is also reduced, providing faster turn-around times, mitigating the delays inherent in electroplating.

E-Clad replaces the negative effects of chroming on both people and the environment, enhances efficiencies, reduces downtime, increases wear life, and in doing so, improves our customers bottom line.

Download our product application document here >> PDF

Change of Ownership of United Surface Technologies

![]() I am excited to inform you that United Surface Technologies is now part of the LaserBond group.

I am excited to inform you that United Surface Technologies is now part of the LaserBond group.

LaserBond Limited is an ASX listed surface engineering company with facilities in NSW, SA and now Vic. The LaserBond and UST businesses are highly complementary in terms of technology, service offering, personnel, research and development and expertise.

The UST business will continue to operate as normal with its quality service and product offering. Existing personnel of UST will remain under the continuing local leadership of Chris Dempsey (General Manager) assisted by Maurice Valimberti (Operations Manager) and Mehdi Soodi (Technical Sales Manager).

Change of Ownership of QSP Engineering

I am excited to inform you that, effective 1 February 2022, QSP Engineering in Queensland is part of LaserBond Limited.

LaserBond Limited is an ASX listed surface engineering company with its head office in NSW, facilities in South Australia and Victoria as well as technology licensees operating globally. Like QSP, LaserBond commenced as a small family business specialising in thermal spraying around 30 years ago. Since then it has dramatically expanded its surface engineering technology offering and its customer base with the development of the LaserBond® cladding process and installation of its first LaserBond® cladding system in 2001. The LaserBond and QSP businesses are highly complementary in terms of technology, service offering, personnel, innovation and customer solution ethos and research and development.

The QSP business will continue to operate as usual, delivering very high quality services and product offerings enhanced by the technical support of the whole LaserBond group. All existing personnel of QSP will remain with the business. Neville Brokenshire, the founder of QSP, will continue to support the business in a transitional role, but operational leadership of the facility will be undertaken by Steve Halloran, LaserBond’s National Production Manager.

LaserBond will provide QSP with significant financial and technical support to continue to grow the business, providing benefits to Australian industry and employing more Australians. LaserBond will continue to invest significant sums in Research and Development, developing new products and solutions, working with industry and local university partners. The acquisition of QSP will augment the manufacturing capacity and flexibility of LaserBond to lower lead times and extend the geographical coverage for the LaserBond reclamation and surface engineering service offering.

Thank you for your ongoing support of QSP. We look forward to continuing to deliver quality services and products, creating superior value for our customers, as part of LaserBond Ltd.

Wayne Hooper

Chief Executive Officer

LEADERSHIP TEAM

Directors

Wayne Hooper GAICD

Chief Executive Officer

Wayne is a professional engineer with significant technical and management experience within the surface engineering, general engineering and manufacturing industries. His engineering experience includes design, maintenance and project management. He started his career within the electricity generation industry, followed by high volume manufacturing. Prior to joining the company in 1994, Wayne also held senior roles in marketing within the building products industry. Wayne holds degrees in Science, Engineering (Honours Class 1) and an MBA.

Wayne is a professional engineer with significant technical and management experience within the surface engineering, general engineering and manufacturing industries. His engineering experience includes design, maintenance and project management. He started his career within the electricity generation industry, followed by high volume manufacturing. Prior to joining the company in 1994, Wayne also held senior roles in marketing within the building products industry. Wayne holds degrees in Science, Engineering (Honours Class 1) and an MBA.

Philip Suriano GAICD

Chairman / Non-Executive Director, Audit, Risk, Nomination and Remuneration Committee Member

Philip has been a director since 2008. He began his career in corporate banking with the State Bank of Victoria (Commonwealth Bank). He holds a degree in banking & finance (B.Bus (Bkg & Fin)). He spent 16 years in senior positions within the Australian Media industry. Philip has gained wide knowledge & experience to give him a strong background in operations, sales and marketing in such roles as National Sales Director, MCN (Austar and Foxtel TV Sales JV) and Group Sales Manager at Network Ten. Prior to joing MCN, Philip was employed within the Victor Smorgon Group. For the past 15 years he has been working in corporate finance.

Ian Neal

Non-Executive Director and Audit, Risk, Nomination & Remuneration Committee Member

Ian's professional background is in financial markets, commencing as an equities analyst and moving to various banking positions until establishing Nanyang Ventures. He is a life member of the Financial Services Institute of Australia, a previous National President of The Securities Institute of Australia and was a member of the first Corporate Governance Council which established the Corporate Governance Guidelines.

Ian's professional background is in financial markets, commencing as an equities analyst and moving to various banking positions until establishing Nanyang Ventures. He is a life member of the Financial Services Institute of Australia, a previous National President of The Securities Institute of Australia and was a member of the first Corporate Governance Council which established the Corporate Governance Guidelines.

Dagmar Parsons

Non-Executive Director and Audit, Risk, Nomination & Remuneration Committee Member

Dagmar has worked with major national and multinational entities in Senior Executive and Non-Executive Director positions, driving critical market success by providing strategic direction, visionary leadership, and innovative thinking. As a Mechanical Engineer, she has an in-depth knowledge of engineering, manufacturing, construction, and service industry environments in the Infrastructure, Oil and Gas, Power, Paper and Steel sectors. She has considerable experience in transforming and growing complex businesses across diverse corporate, operational and entrepreneurial roles in Australia, Asia and Europe. She is a graduate member of the Australian Institute of Company Directors.

Dagmar has worked with major national and multinational entities in Senior Executive and Non-Executive Director positions, driving critical market success by providing strategic direction, visionary leadership, and innovative thinking. As a Mechanical Engineer, she has an in-depth knowledge of engineering, manufacturing, construction, and service industry environments in the Infrastructure, Oil and Gas, Power, Paper and Steel sectors. She has considerable experience in transforming and growing complex businesses across diverse corporate, operational and entrepreneurial roles in Australia, Asia and Europe. She is a graduate member of the Australian Institute of Company Directors.

Matthew Twist GIA (Aff.)

Company Secretary, and Chief Financial Officer.

Matthew has over 25 years financial management experience, encompassing financial and operational control and systems development in manufacturing. Matthew has been the company's Chief Financial Officer since March 2007, and was appointed Company Secretary in March 2009. Matthew has a Certificate in Governance Practice, and is an affiliated member of the Governance Institute of Australia.

Matthew has over 25 years financial management experience, encompassing financial and operational control and systems development in manufacturing. Matthew has been the company's Chief Financial Officer since March 2007, and was appointed Company Secretary in March 2009. Matthew has a Certificate in Governance Practice, and is an affiliated member of the Governance Institute of Australia.

Senior Managers

Thomas Schlaefer

Research & Development Manager

Thomas is a materials and process expert out of Germany who leads our R&D department. He achieved his Ph.D. in mechanical engineering at the Surface Engineering Institute of RWTH Aachen University, Germany, which is one of the leading research institutes for coating materials and processes. He has extensive experience and knowledge of materials and coating processes, and technical skills related to laser cladding, application oriented coatings development, materials development, and materials and composites analysis.

Thomas is a materials and process expert out of Germany who leads our R&D department. He achieved his Ph.D. in mechanical engineering at the Surface Engineering Institute of RWTH Aachen University, Germany, which is one of the leading research institutes for coating materials and processes. He has extensive experience and knowledge of materials and coating processes, and technical skills related to laser cladding, application oriented coatings development, materials development, and materials and composites analysis.

Steve Halloran

Operations Manager (New South Wales & Queensland)

Steve has led our NSW operations, including estimating, since 2012. Steve has recently taken the post of Production Manager overseeing our Queensland operations. He joined LaserBond in 2007 as an experienced tradesman and is fully conversant in our diverse operational divisions. Steve holds a Cert III Mechanical Engineering Trade Certificate.

Steve has led our NSW operations, including estimating, since 2012. Steve has recently taken the post of Production Manager overseeing our Queensland operations. He joined LaserBond in 2007 as an experienced tradesman and is fully conversant in our diverse operational divisions. Steve holds a Cert III Mechanical Engineering Trade Certificate.

Chris Dempsey

Operations Manager (South Australian & Victorian)

Chris is an accomplished Senior Engineer Professional with extensive technical and management experience including manufacturing and oil & gas industries. He provides global experience in technical design, engineering, project management, operations management and senior leadership roles. He brings over 25 years of technical, business unit management and leadership to the LaserBond Victorian & South Australian facilities. He holds a Bachelor of Engineering - Mechanical (Hons). .

Chris is an accomplished Senior Engineer Professional with extensive technical and management experience including manufacturing and oil & gas industries. He provides global experience in technical design, engineering, project management, operations management and senior leadership roles. He brings over 25 years of technical, business unit management and leadership to the LaserBond Victorian & South Australian facilities. He holds a Bachelor of Engineering - Mechanical (Hons). .

Tahnee Bathurst

Project Engineer – R&D

Tahnee is responsible for co-ordinating and conducting in-house and external R&D projects. Her background in Chemistry has enabled her to effectively maintain and run LaserBond's in-house laboratory since joining the team in 2014. She has a broad knowledge of surface engineering techniques, coatings and material selection, and metallographic examination techniques. She has attained certificates in Metallurgy and Metallography.

Tahnee is responsible for co-ordinating and conducting in-house and external R&D projects. Her background in Chemistry has enabled her to effectively maintain and run LaserBond's in-house laboratory since joining the team in 2014. She has a broad knowledge of surface engineering techniques, coatings and material selection, and metallographic examination techniques. She has attained certificates in Metallurgy and Metallography.

Peter Oke

Quality Manager

Peter leads our Quality division focused on maintaining and continuously improving LaserBond's quality assurance and control strategies, documentation and procedures. He provides a wealth of experience from quality and project management roles in diverse industries including manufacturing and aviation.

Peter leads our Quality division focused on maintaining and continuously improving LaserBond's quality assurance and control strategies, documentation and procedures. He provides a wealth of experience from quality and project management roles in diverse industries including manufacturing and aviation.

Wayne Hooper (CEO) May 19 Presentation & Interview with Finance News Network

Wayne Hooper was invited by Finance News Network to present at their May 2019 Investor Event. Link to videos:

The Interview

The Presentation

Related Articles

LaserBond Heat treatment in Adelaide, SA and Sydney, NSW

We owe much to inventions such as the open-hearth furnace and the Bessemer process to remove the impurities from molten pig iron and transform it into versatile steel. Once an object is manufactured with this strong and sturdy ...read more.

Benefits of Vacuum Heat Treatment for Stainless Steel Heat Treating in Sydney

If you manufacture parts, equipment or machinery for capital-intensive industries (those who rely on their machinery to do their job), you need to assure them your products are durable, easily repairable and extra reliable. ...read more.

Protect Your Equipment with Stainless Steel Vacuum Heat Treatments

In industrial settings, the machines and production lines are critical to operations. No matter the specific items that you’re producing at any given point, you rely on your machines to do their jobs consistently and reliably. ...read more.

Expand the Lifespan of Valuable Equipment with the Help of Laser Cladding Companies in Sydney, NSW or Adelaide, SA

When it comes to your company’s equipment and machinery, your goal is a complex one: to maximise wear life, performance and productivity of capital-intensive equipment while also minimising downtime and maintenance cost. How can you ...read more.

High-Power LaserBond® Laser Cladding at Sydney, NSW and Adelaide, SA for High-Quality Surfaces

Do the metal parts in your machines wear out much too quickly to your liking? You keep a substantial stock of replacement parts, but the number of items constantly seems to dwindle, much more rapidly than it should. Machine ...read more.

Laser Cladding Services Available in Adelaide, NSW, Sydney and SA Through LaserBond

Unfortunately, metal parts do not last forever, and if they are used constantly, it may seem as though their lifespan is limited. Replacing machinery can cause a headache for any owner. Over and above the physical annoyance, the price tag ...read more.

The Benefits of Laser Cladding Services and How to Find the Best Companies for the Job

In capital heavy industries, such as mining, utilities, automotive, industrial and aviation, it’s crucial to keep machinery in full working order. When your equipment breaks down, core business processes cease, and the resulting lost ...read more.

LaserBond Provides Laser Hard Facing in NSW, Sydney, SA, and Adelaide

Are you concerned about the wear and tear on your machine parts? Are you looking for a way to expand their lifespan? If so, you should consider laser hard facing. Laser hard facing in NSW is a practice that puts the highly trained ...read more.

What Remanufacturing Can Do for You: Discover Benefits from Adelaide to Sydney to SA to NSW

Have you ever considered investing in remanufacturing? At LaserBond, our remanufacturing service takes your used or worn surface engineered parts and restores them to their original performance with a result that is equivalent to ...read more.

Protective Thermal Spray Now Available in NSW, Brisbane, Sydney, and Melbourne

At LaserBond, we have been providing specialist surface engineering services since 1992. During that time, we have found our passion in the advancement and optimal utilisation of materials and technologies to increase operating ...read more.

Protective Thermal Spray now available in Sydney, Melbourne and Adelaide

Technology we license

Much of our surface engineering technology and processes have been developed in-house through our R&D facilities. These technologies are available for licensing in a range of markets.

Services we offer

Our capabilities incorporate a unique range of advanced surface-engineering technologies and processes designed to enhance the life and performance of machinery, equipment and production-vital components.

Products we make

We develop and manufacture an exclusive range of surface- engineered products, embedded with our patent technologies that will extend component wear-life by 3 – 7 times.

- Decreased repair costs: It is often a strong choice to repair something before you opt to buy a new one. When you get a thermal spray in Sydney completed by a professional, your part or item is protected by damaging elements found around your worksites on an everyday basis without an all-new part investment.

- Less heat input: Apart from a few exemptions, the thermal spray process leaves the component’s thermal history alone. This means that heat will not be a concern when you’re considering protecting the condition of your components.

- All the options: Almost every metal, ceramic, and plastic can be thermally sprayed. Many of your parts and components could benefit from a thermal spray. Don't wait for an issue to accrue; take the initiative and spray today.

What Remanufacturing Can Do for You: Discover Benefits from Adelaide to Sydney to SA to NSW

Technology we license

Much of our surface engineering technology and processes have been developed in-house through our R&D facilities. These technologies are available for licensing in a range of markets.

Services we offer

Our capabilities incorporate a unique range of advanced surface-engineering technologies and processes designed to enhance the life and performance of machinery, equipment and production-vital components.

Products we make

We develop and manufacture an exclusive range of surface- engineered products, embedded with our patent technologies that will extend component wear-life by 3 – 7 times.

- Minimise wear: By remanufacturing your parts, you virtually roll back the clock, turning these parts back into a functional part of your surface engineering system. When you remanufacture your products, you are ensuring that all the worn parts are replaced without replacing the item itself.

- Increased production: By replacing the worn components of your parts, we can restore your item to full functionality. Our reliable remanufacturing process means that when the part is in use, it will work the way you need it to and continue to function reliably.

- Reduced downtime: With everyday part use comes wear and tear; that is common knowledge for professionals across all industries. When your parts become worn down, you will no longer have to stress about your machine's downtime significantly impacting your production schedule. With LaserBond remanufacturing in SA, you can send in your item to us and trust we will return it to you efficiently. With minimal downtime, your business can enjoy full productivity with your remanufactured parts as quickly as possible.

- Control your environmental impact: There are many benefits to remanufacturing your parts in Sydney, but one factor quickly gaining steam across Australia is the environmental benefit. Remanufacturing helps your business to do its part to protect the environment and reduce your professional environmental impact. By using the same components and their materials for longer before investing in brand-new manufactured parts, you are actively reducing your energy use and helping to prevent harmful emissions in the air and water.

LaserBond Provides Laser Hard Facing in NSW, Sydney, SA, and Adelaide

Technology we license

Much of our surface engineering technology and processes have been developed in-house through our R&D facilities. These technologies are available for licensing in a range of markets.

Services we offer

Our capabilities incorporate a unique range of advanced surface-engineering technologies and processes designed to enhance the life and performance of machinery, equipment and production-vital components.

Products we make

We develop and manufacture an exclusive range of surface- engineered products, embedded with our patent technologies that will extend component wear-life by 3 – 7 times.

What You Should Know About Laser Hard Facing in Sydney

The Benefits of Laser Cladding Services and How to Find the Best Companies for the Job

Technology we license

Much of our surface engineering technology and processes have been developed in-house through our R&D facilities. These technologies are available for licensing in a range of markets.

Services we offer

Our capabilities incorporate a unique range of advanced surface-engineering technologies and processes designed to enhance the life and performance of machinery, equipment and production-vital components.

Products we make

We develop and manufacture an exclusive range of surface- engineered products, embedded with our patent technologies that will extend component wear-life by 3 – 7 times.

-

Search for companies with a wealth of experience

It takes years of research and development to perfect techniques of laser cladding which guarantee results. We know how to treat surfaces of all types of metal with absolute precision, which is why many of our customers are internationally-recognised OEM manufacturers. -

Choose a service which prioritises customer care

You need a company that can explain the complexities of their services in layman’s terms, especially if you have customers who are curious for answers. We’re always available to offer support when required, and the only thing that rivals the quality of our service offering is our commitment to prioritising our clients’ needs. -

Check the company’s credentials

Reputable laser cladding services should be able to prove their treatments work. As industry leaders in innovation, we continually invest in the research and development of our highly regarded surface treatment solutions, ensuring we remain at the cutting-edge of technological advancements. Ask us for examples of previous work and customer testimonials to find out how effective our services are. -

Find a company which offers a range of services

Laser cladding isn’t the only way to alter the surface of a metal component or bond an outer surface to its substrate, which is why finding laser cladding companies that offer alternative services is a wise idea. Our offering includes vacuum heat treatments, thermal spraying, welding, machining and much more, ensuring we have the solution you need to extend the lifespan and improve the performance of your metal components and heavy machinery.

Laser Cladding Services Available in Adelaide, NSW, Sydney and SA Through LaserBond

Technology we license

Much of our surface engineering technology and processes have been developed in-house through our R&D facilities. These technologies are available for licensing in a range of markets.

Services we offer

Our capabilities incorporate a unique range of advanced surface-engineering technologies and processes designed to enhance the life and performance of machinery, equipment and production-vital components.

Products we make

We develop and manufacture an exclusive range of surface- engineered products, embedded with our patent technologies that will extend component wear-life by 3 – 7 times.